Our Expertise

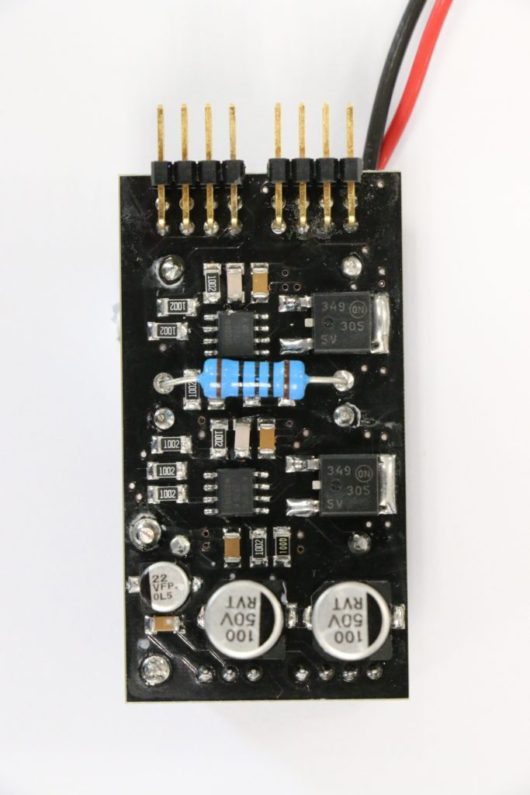

Since 2009, ART logics has been offering a broad range of testing, certifications and supply chain management solutions. It offers up-to-date testing equipment to ensure safety and reliability and offering improved longevity, durability and functionality for any type of ECU.

ART logics is a designer and manufacturer of a new generation of more “automotive efficient” equipment’s solutions for all automotive embedded electronic controllers function, reliability and series production test systems integration. The R/D team is constantly working on building innovative testing equipment with high-performance in order to meet any safety standards or customer needs.

Engineers offer their expertise to bring you constant new technologies at your service.

ART logics wants to be a new testing equipment reference brand for the automotive embedded electronic industry.

Example of Controllers covered by ART logics testing platform:

- The body controllers with their large number of signals mixing high current and low current ones, digital and analogs as well as RF signals requirements for some of them

- The airbag controllers with their firing loops fault simulation specific needs as well as their crash signal to monitor at a fast sampling rate to verify it’s pulse shape and amplitude.

- The electrical power steering brush and brush less controllers with the torque and angle synchronized signals to be generated, the high power currents handling involving complex ground loop issues to manage, the 3 phases motors complex simulations.

- The transmission controllers with the synchronous encoder signals to generate, the PEPS passive entry passive safety, the ABS and ESP controllers with the complex valve tests signals to monitor.

- All the above with 1 single platform allowing benches and tests resources and switch from one type of controllers test to be reused within 5 min: the disconnection and re-connection time of the load box to the TCU100.

Best Solutions

The same solution is used for the new energy technologies management controllers of the EV/HEV cars: the VCU controller, the BMS controller with the possibly very large number of battery cells to simulate at high accuracy voltage signals and possibly high current as well for the cells charge and discharge tests, the BMU controller with the very high voltage signals to generate and the Inverter/MCU with the very high voltage and also very high current pulse signals to generate for the sensitive correct assembly verification test and the calibration tests.

Experience cumulated over the last 5 years:

- Over 110 ART systems and 250 TCU100 distributed

- More than 85 different system integration projects

- >45 different customers, >500 test positions configured